The BMW 1 Series has only been showing up on people's driveways in the States for a few months now and already there are enthusiasts ready and willing to fine tune it. A great performance car straight out of the box, it none-the-less comes with the compromises every modern car has. We've talked about this often enough: in order to satisfy the government's regulators, insurance lobbies, and the average consumer, new cars are "sanitized for our protection."

The owner of this particular 135i decided to tweak his car before the break-in process was complete, arguing that you might as well make the car what you want it to be right from the start. Our kind of guy. The biggest item on his list of things to do was eliminate the well documented understeering characteristic that pretty much plagues every new car these days (according to the lawyers, understeer handling is much easier to deal with-- and thus safer-- for most average drivers). He already had specially tuned sway bars installed before he came to our shop; and now he wanted us to install a complete Variant 2 KW brand coil-over suspension to further button down the handling.

First introduced on the E60 5 Series cars, the front suspension of the 1 similarly utilizes a complex multi-link front suspension with standard strut dampers. The photo below shows the front hub assembly removed and suspension partially disassembled (note the stock 6 piston brake caliper cradled on the red towel):

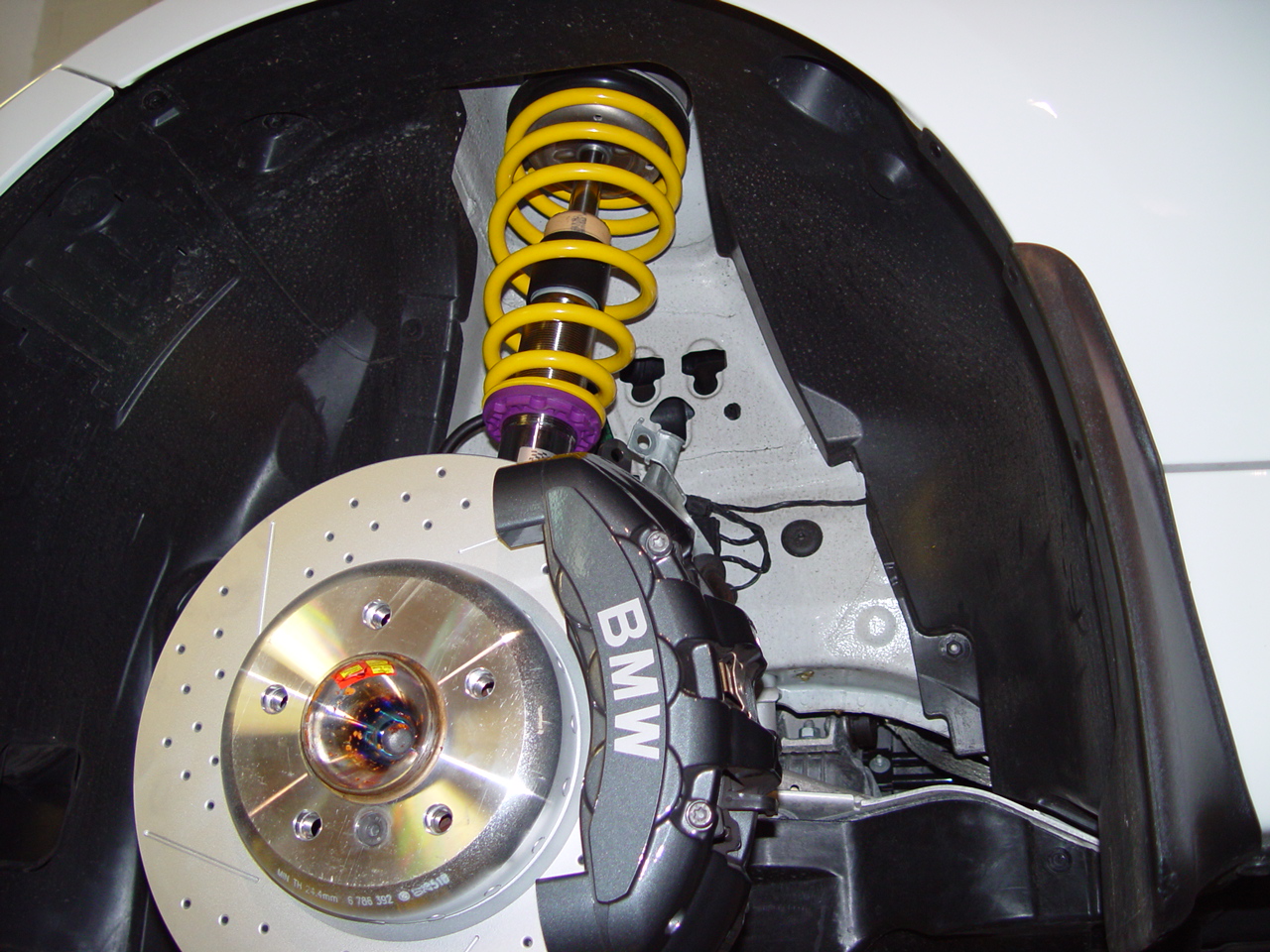

Here you can see the KW front strut assembly installed:

While it looks pretty complex-- and make no mistake it is-- we've done enough of these BMW suspension swaps to know the tricks to do it properly without damaging any of the ball joints and links.

The rear suspension is typically easier to work on because there is no steering gear to get in the way. But, it still takes time and the proper tools. The entire trunk needs to be de-trimmed to get to the upper shock mounts. And-- again to do it properly-- we used a special spring compressor to get the stock springs out:

Here you can see the KW suspension installed (note the polished stainless steel damper and the height adjustable spring perch in purple):

We're big fans of KW suspensions, and this kit did not disappoint. The welds looked great, the hardware was top notch, and everything fit as it was supposed to. To start things off, we set the ride height about one half inch lower than stock. The springs will settle some and when the customer comes in for an alignment we can tweak the height.