Cracking up: E46 Sub-frame issues Part 2

We already talked about issues with the E46 series BMW rear sub-frames in an earlier post, here is some follow-up information. The amount of damage on the vehicle in question was so bad that we decided to have the OEM sheet metal replaced completely instead repairing it by welding. Thankfully BMW stood behind their product and actually warrantied the repair portion of the work.

We sent the car to AutoMark, an authorized BMW body shop, for the sheet metal replacement.

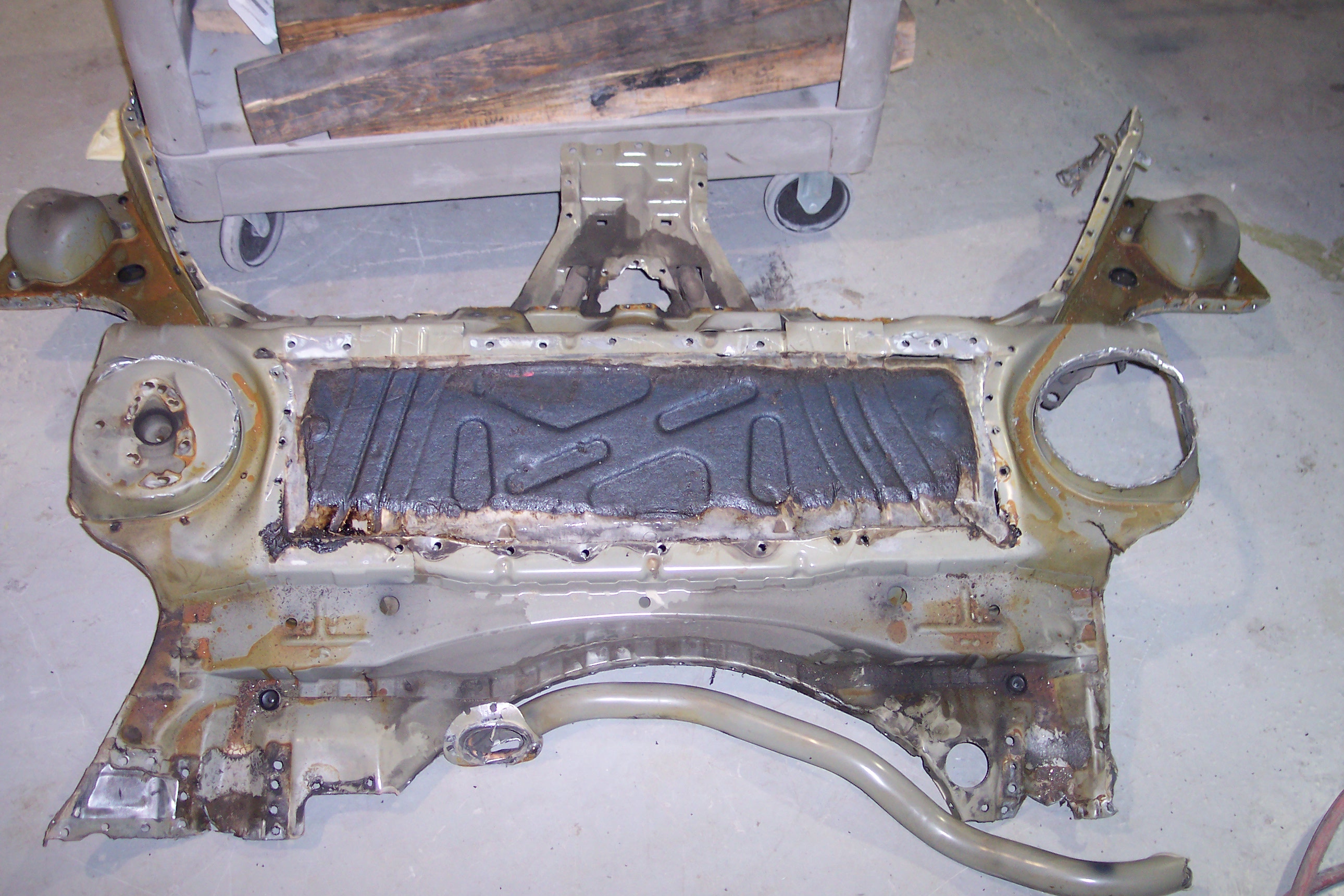

Out with the old:

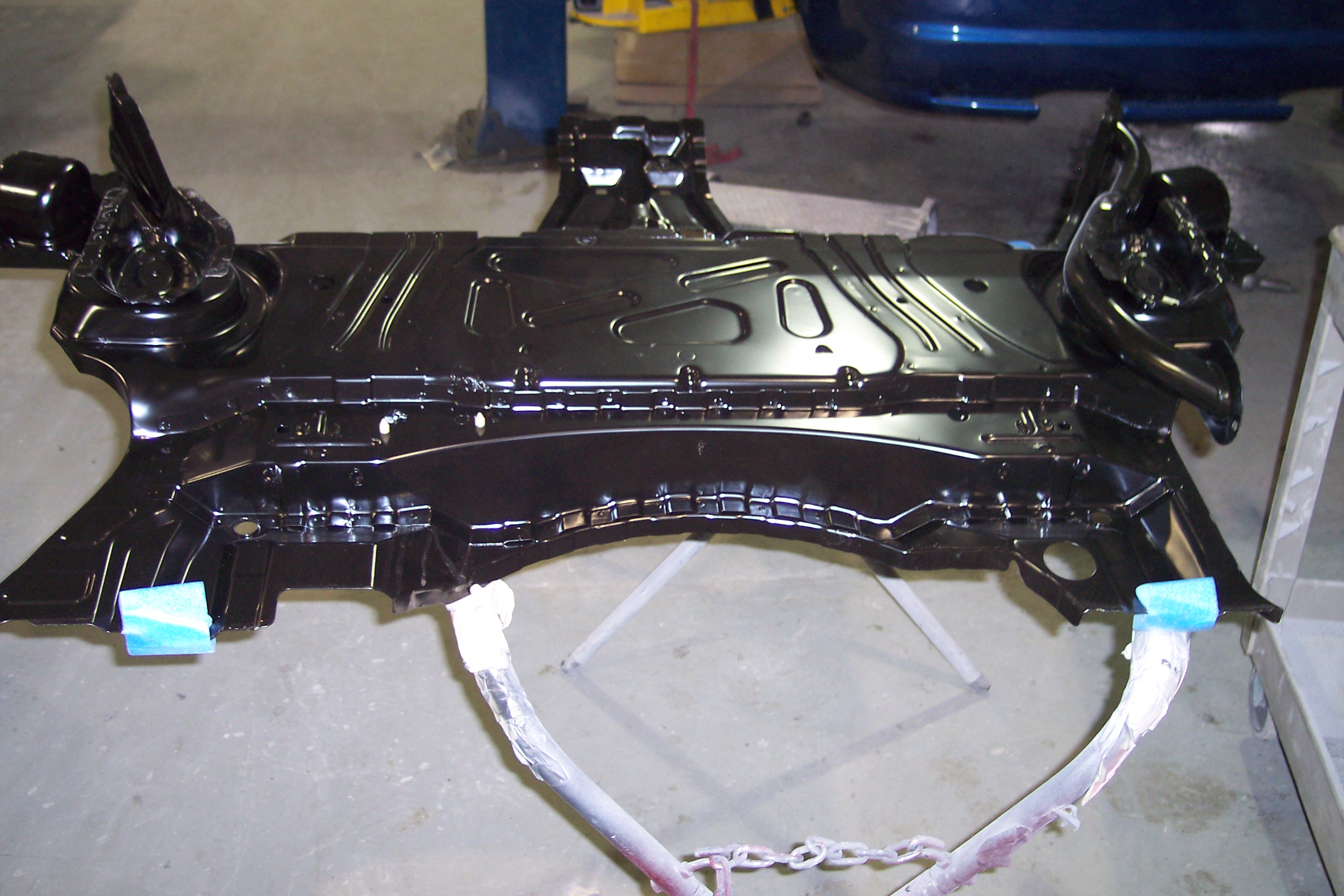

And in with the new:

Undercoating re-applied to the new sheet metal:

After we got the car back, we essentially had to start over with the reinforcement procedure. First we had to grind away all the undercoating material to prep the areas for weld. Here you can see the front reinforcement plate welded onto the OEM body panel. The hole in the center is where the stud goes. The welded hole to the right is used to further bond the plate to the body. Note the hole on the left with the tan insulating material around it. This material, which is sprayed in between the body panels and structure for sound deadening and weather proofing really gave us fits. When the material heats it turns to liquid and comes pouring out of any hole or crack. Our welder switched from side to side so as to not heat the material up too much, but it was unavoidable. The sticky mess doubled the welding time to about 4 hours.

Below is view of the trunk as it came back from the body shop. There were several holes, and even a few cuts in some of the surrounding sheet metal that was made by the audio equipment installer.

This shows where we needed to cut access holes. Just beneath these areas are the structural components where the rear sub frame mounting bolts are attached.

Here is a detailed look into the access hole and the second cut, and extra welding we had to make in the structural beam under the trunk’s sheet metal skin.

New plate custom formed and welded into place.

Though these failures are relatively rare, they do occur on higher mileage cars that have had a rough life. As you can see by the two entries posted, the process to repair and reinforce the area is straightforward but very involved. This repair can easily cost over $10,000 including the replacement of the OEM sheet metal. The lesson is to inspect this area frequently, and/or add the reinforcement package before the sheet metal fails.