The second phase of our E30 M3 winter project is to tackle the suspension (see E30 M3 Rebuild: Brakes for phase one). We began by first inspecting the suspension on the ground as well as checking to see how the car behaved dynamically on the road. We decided, along with the car's owner, to go ahead and replace the dampers at all four corners, upgrade the sway bar size to help flatten the cornering characteristics as well ad eliminate some of the understeer, and replace some of the worn out suspension bushings. We tried to replace every stock part with a more performance oriented equivalent since the car will primarily be a track tool and not a boulevard cruiser. That means the around town ride quality may suffer a little, but with the payback coming on the track.

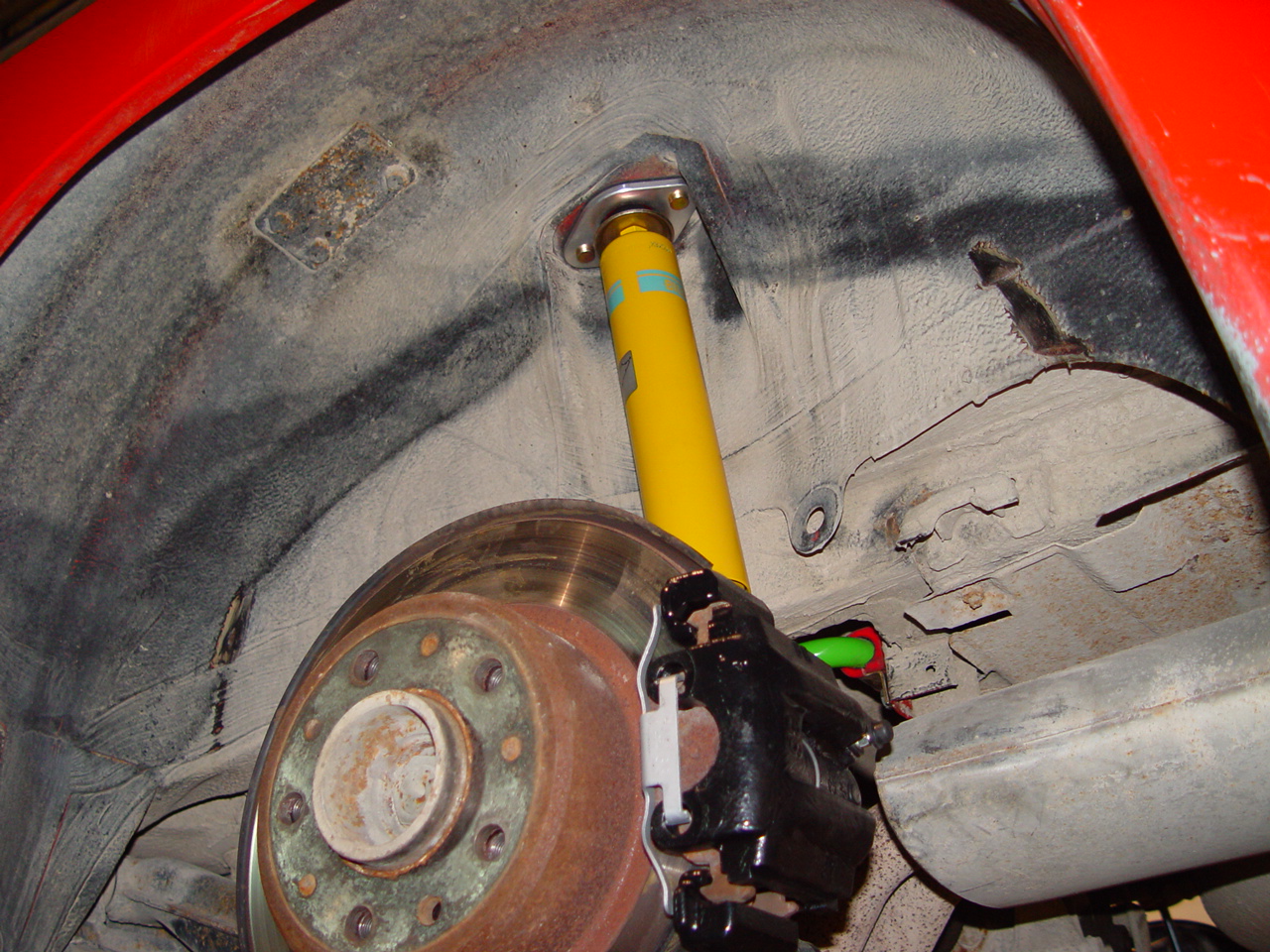

We went with Turner Motorsports J Stock spec Bilstein dampers. The rear dampers (shocks) are a new inverted design, meaning that the body of the damper is mounted at the top and the piston rod is attached to the suspension arm. This reduces the amount of unsprung weight carried at the rear which theoretically helps in handling. Here you can see the damper body and the upgraded upper shock mount:

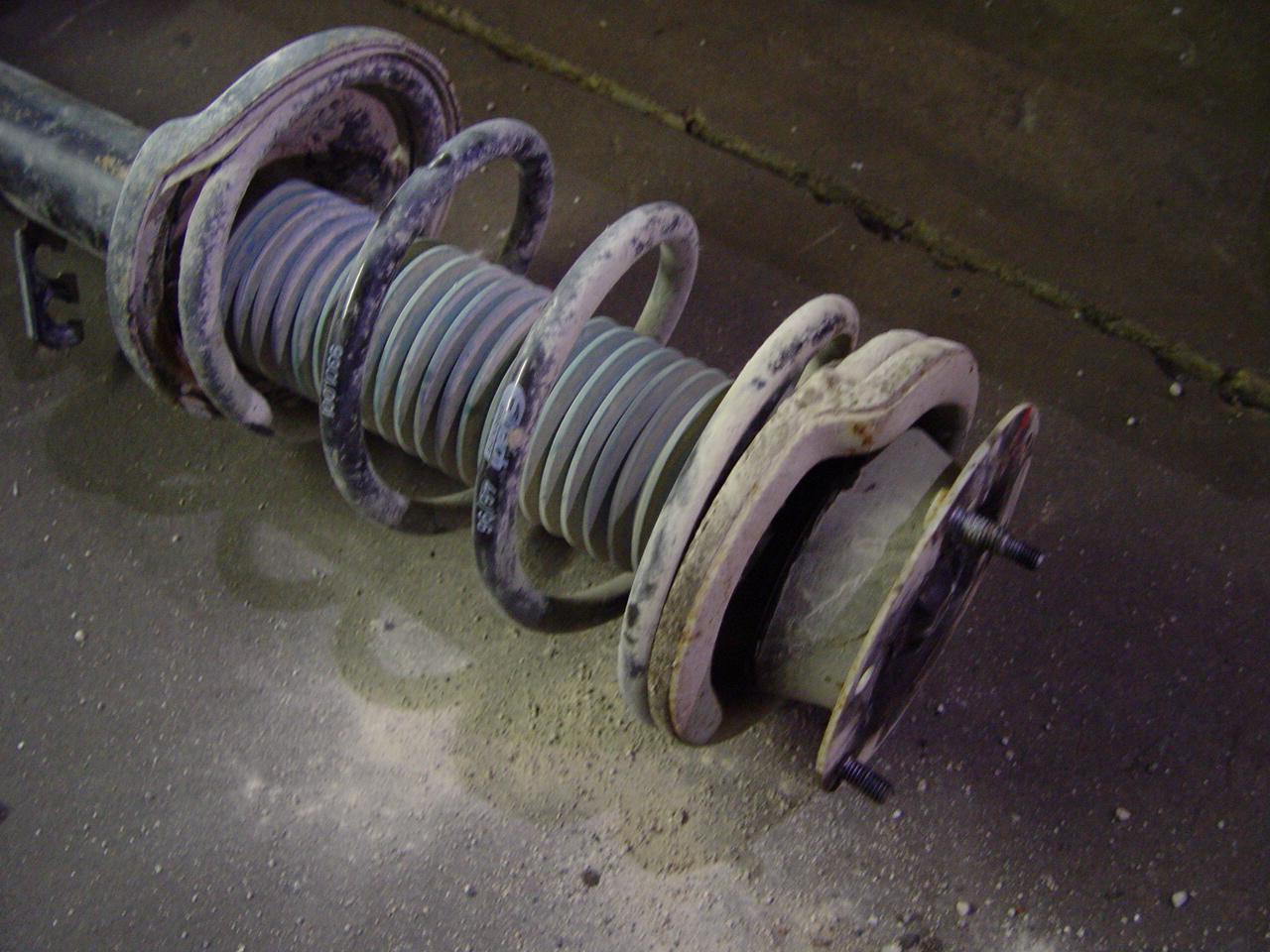

The front strut suspension on an E30 M3 uses damper inserts or cartridges. In other words, the damper body in inserted into the strut housing and is trapped, along with the coil spring by the upper mount. Here is the entire strut assembly removed from the car:

Thanks to time and road conditions, a great deal of dirt and muck found its way into the strut assembly and dampers:

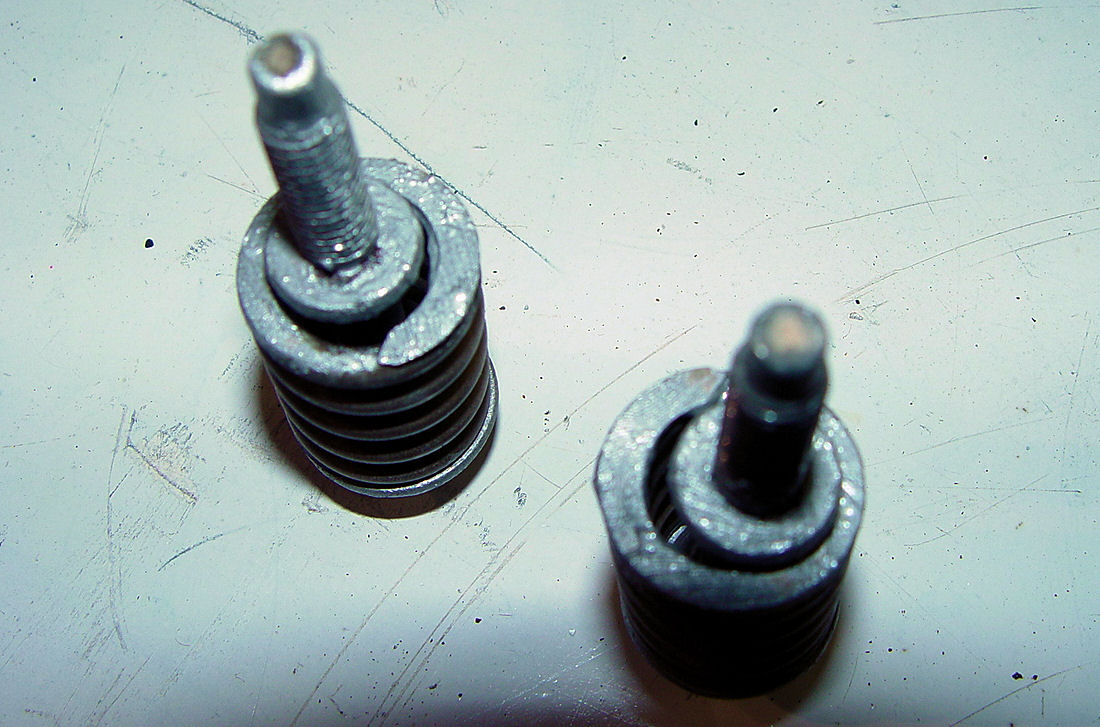

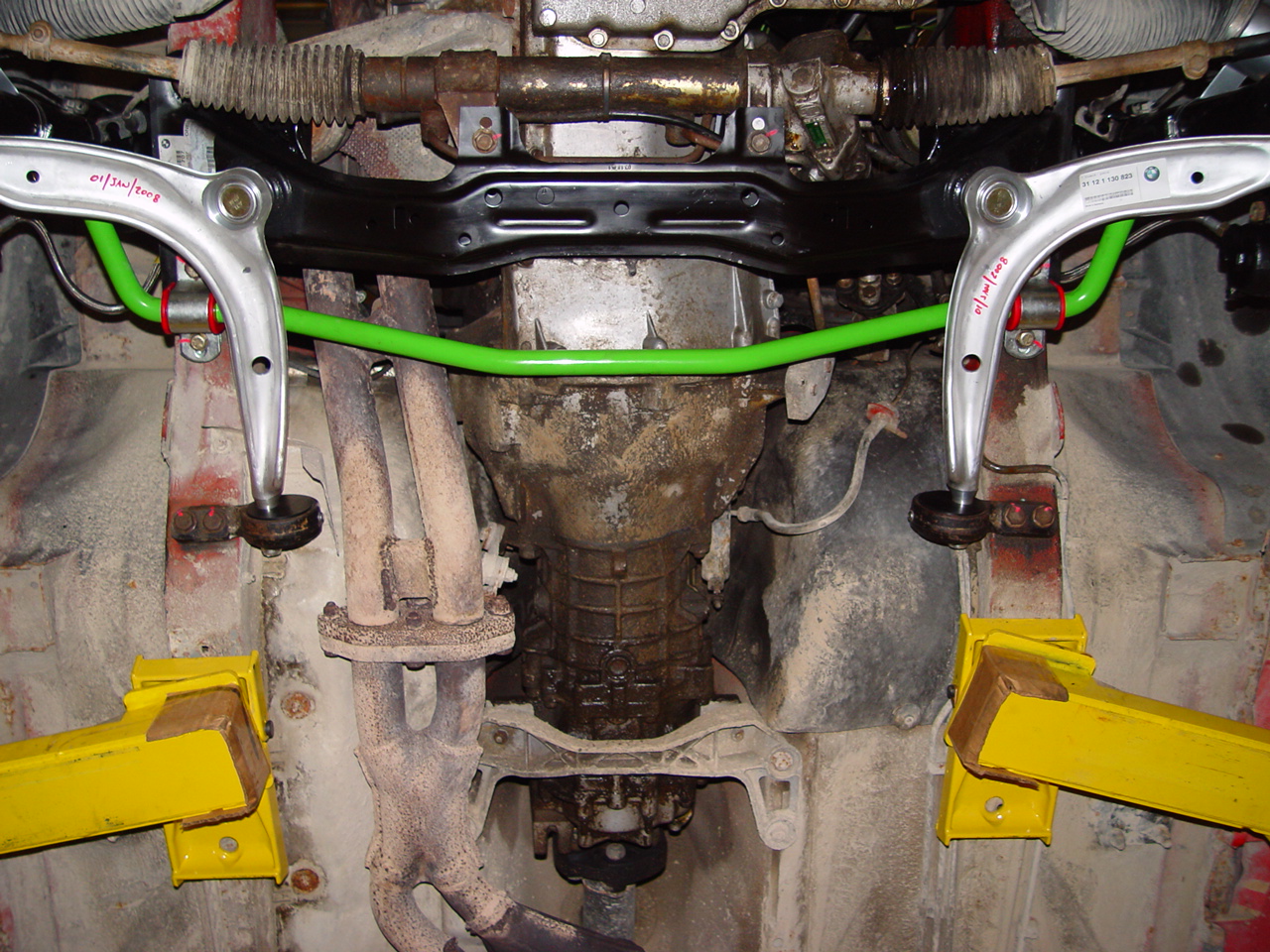

Since the front strut assemblies were out of the way, it was a good time to replace the front lower control arms. The control arms on earlier E30 models were made of steel. Later BMW began using aluminum arms, to save on unsprung weight. The problem with the aluminum arms is that they tend to fail sooner than the steel ones. It is common practice therefore to replace these arms, along with the ball joints, on a regular basis. We opted for the OEM aluminum arms, noting the date they were replaced for future reference (see paint marks):

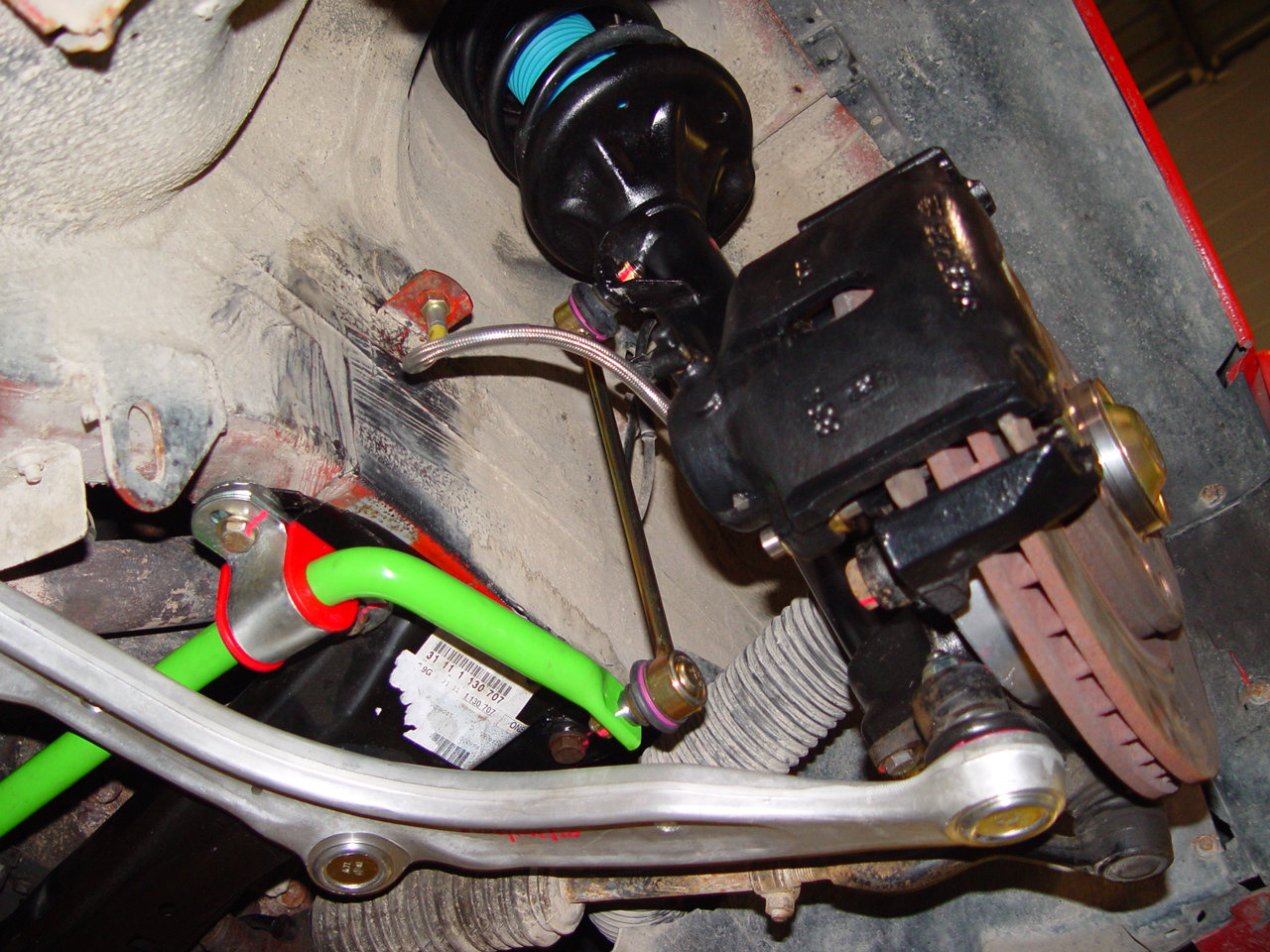

In the above picture you can also see the new ST brand sway bar as well as the offset Delrin lower control arm bushings (the rear most mounting bushing on the control arms). As noted earlier, we decided to replace stock componentry with higher performance aftermarket equipment where it made sense. The stock bushings are made of soft rubber to help isolate the noise and vibration coming from the front suspension into the cabin. The downside is that the rubber allows the arms to move about under load, changing the suspesion dynamics especially in corners. The more solid Delrin material eliminates this potential motion and helps "tighten up" the front end. Having the mount offset adds camber and caster compared to stock, an added benefit at the track.

A close look at the photo will also reveal that the front axle carrier, or sub-frame, is new. Here's another weak link in the E30 suspension and an item well worth checking out while your mucking about in that area anyway. Thankfully we went ahead and checked, since it had indeed failed:

The area around the engine mount failed completely on the passanger side, and cracks were evident on the drivers side:

A brand new carrier is relatively cheap (considering how important of a safety itme it is) so we went ahead and ordered a new one from BMW. But before we installed it, we reinforced the weak areas by first welding a plate to the mounting surface, doubling the thickness of the steel:

Then we welded on another piece and essentially created an utlra strong box section:

Taking these simple but vital steps will assure that the suspension will be up to the rigors of track driving.

Here you can see all of the parts back on the car including the rebuilt brake calipers, new brake lines, brake cooling backing plate, new wheel bearings, new sway bars and sway bar links, lower control arms, lower control arm bushings, upper strut mounts (offset 30 mm for added camber), new dampers and custom reinforced axle carrier.